Zhafir Venus II Series Injection Moulding Machine

| Fully electric drives for clean and quiet operation |

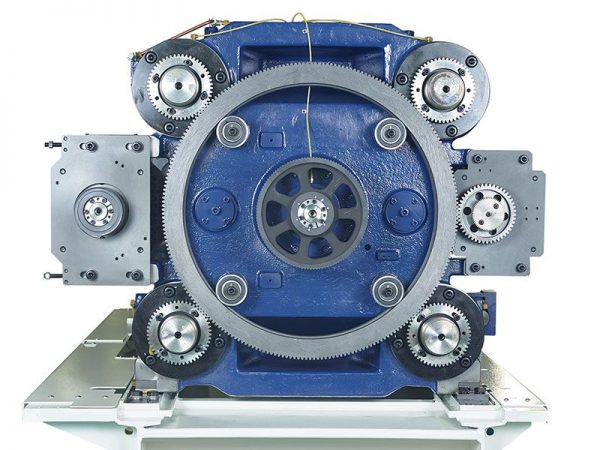

| Intelligent motion control for short dry cycle times |

| Tailor-made servo drives |

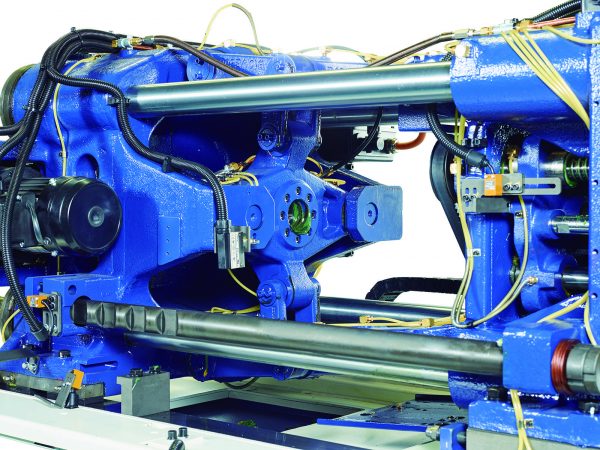

| Square tie bar distance for more freedom |

| Linear guides (optional) |

| Intelligent mold protection |

| Application-oriented injection units |

| Latest control technology |

Zhafir Venus II Series has been now replaced with a new model Zhafir Venus III Series. Please click to view details of our new model.

Zhafir Venus III Series Injection Moulding Machine

Zhafir has been making greater impact on the market for electric injection-molding machines than almost any other manufacturer. This is substantiated not just by the dynamic sales growth and the fast-increasing inquiries that Haitian International’s sales teams receive around the globe. Since the introduction 10 years ago, the Zhafir solutions rose to the second strongest brand in Asia.

With clamping force sizes of 400 to 8,000 kN and specifically modified performance versions such as the “Venus p”, “Venus h”, and “Venus hs”, Zhafir already offers by far the most extensive portfolio of fully electric machines. High quantities and a tremendous depth in production within the Haitian Group guarantee a first-class price-performance ratio in future as well.

Sliders for moving platen support heavy mold weight and reduce the coefficient of friction. The Platen moves smoother and can be replaced and maintained very easy.