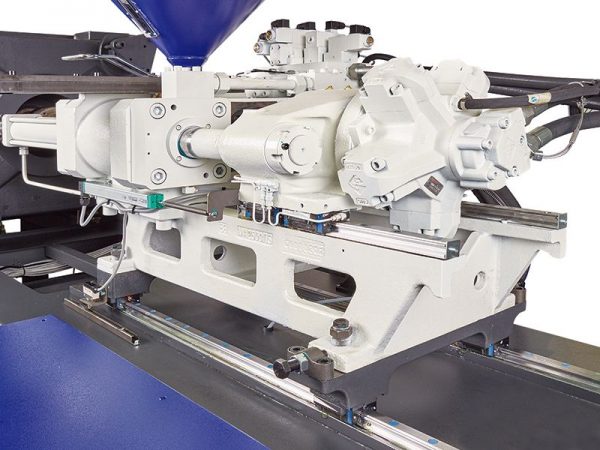

Haitian Mars IIS Series Injection Moulding Machines

| Available from 600 to 33,000 kN |

| World’s best-selling injection molding machine |

| New high-drive servo system (developed by Haitian) |

| Fully improved design structure |

| Full closed-loop process, high repeat accuracy |

| Energy saving |

| Interactive with open integration |

Haitian Mars II Series has been now replaced with a new model Haitian Mars III. Please click to view details of our new model.

Haitian Mars III Series Injection Moulding Machine

The Haitian Mars Series has been on the market for over 10 years and continues to be the top of the line in hydraulic injection-molding technology – the world’s best-selling injection-molding machine. Since its market launch in 2006, more than 200,000 units of the Mars Series have been delivered.

The upgraded Mars – so called „II S“ – comes with a lot of design improvements, which provides more reliable hardware to maximize the energy efficiency while improving the precision. The common design enables Haitian Plastics Machinery to deliver 30.000 machines and more per year in a short delivery time.

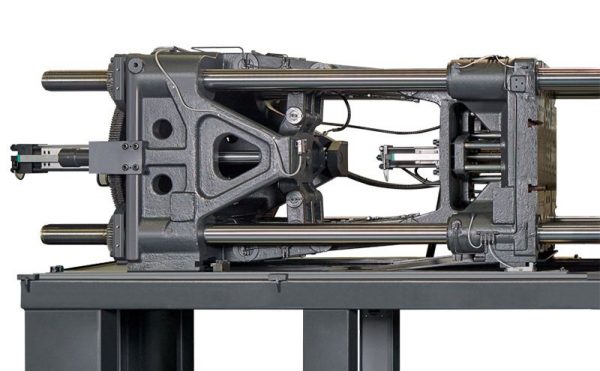

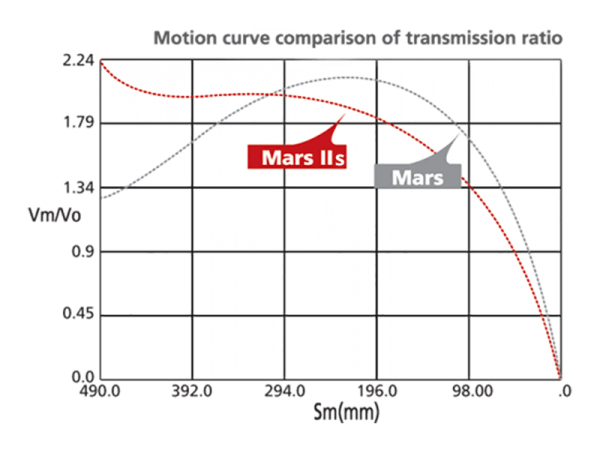

Graphic shows an example of 200-ton clamping unit

Vm: Moving speed of movable platen

Vo: Moving speed of oil cylinder

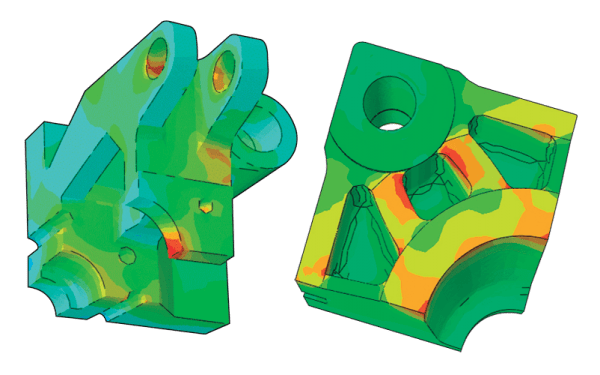

The result: higher rigidity and stability.

Providing better lubrication and lower lubrication consumption. A smooth operation leads to longer lifetime of the clamp. Less maintenance required.

Providing better lubrication and lower lubrication consumption. A smooth operation leads to longer lifetime of the clamp. Less maintenance required.

- High-performance KEBA or TECHMATION control

- Mold profile data memory

- New performance for production monitoring

- User-friendly user interface

- Comprehensive software functions

- Clear and simple button to re-layout

- Shortcut configuration for clear identification

- Multi-language available