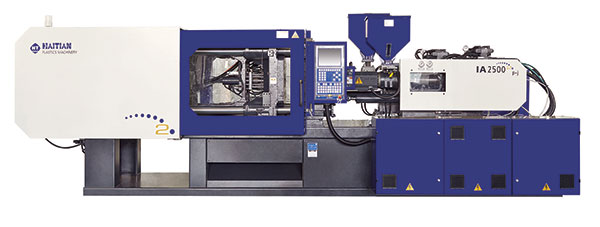

Haitian Iapetus II Series Injection Moulding Machine

TECHNOLOGY TO THE POINT

| Available from 1,200 to 18,500 kN |

| 6 different variations for different application requirements |

| Optimized 5-point double toggle system |

| Energy saving Mars Technology inside |

Haitian Iapetus II Series has been now replaced with a new model Haitian Iapetus III. Please click to view details of our new model.

Haitian Iapetus III Series Injection Moulding Machine

Serving as an industrial leader and a technical pioneer in the field of plastic injection molding machines, Haitian started to research and develop multi-component injection molding machines in the early 1990s. Today, the company has yielded substantial results.

Our company philosophy of “Creating and Extending Advantage” for our customers is paramount in our commitment for research and development for multicomponent and multi-color plastic Injection molding machines.

Get In touch

.

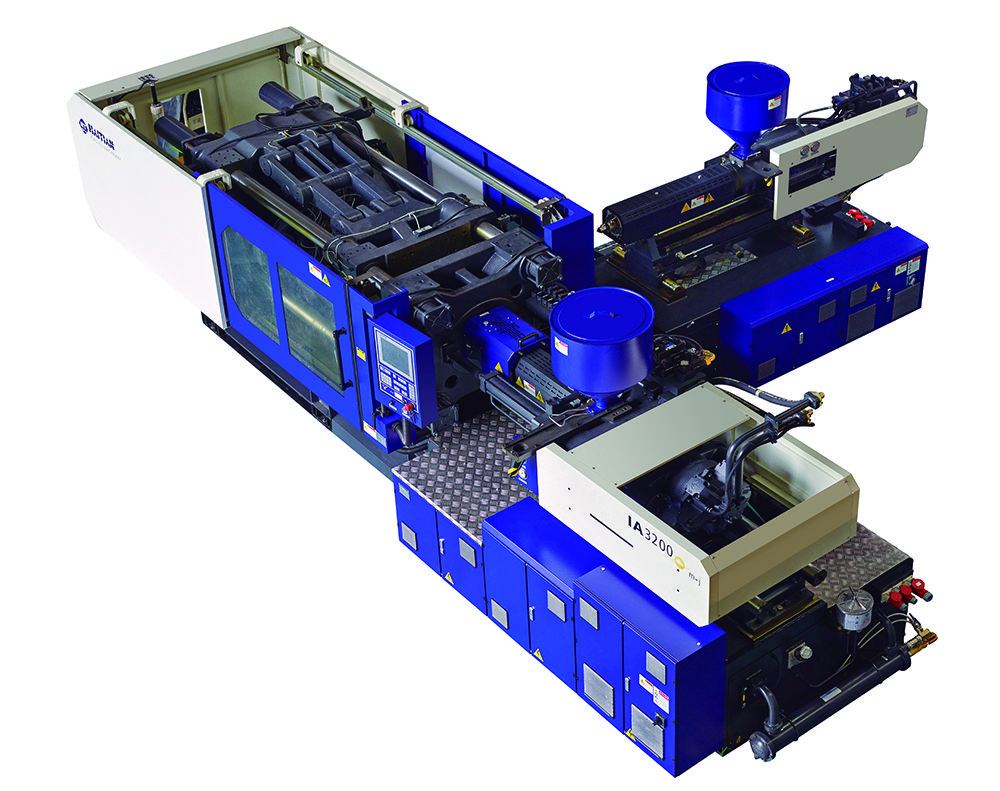

Customized Turntable

The large Multi-component turntable machine is customized to the customer’s requirement for different applications. Large mold rotation capacity , reliable bearing of rotary table, precise rotation, customized plasticizing units, high efficiency energy-saving system.

Space Saving P-Version

INTEGRATED PARALLEL SINGLE CYLINDER INJECTION UNITCompact structure, simple appearance, high modularized, a more flexible composition of the injection unit

Co-injection solution

The Iapetus IAⅡ/m Series was constructed according to costumer demand, its clamping unit does not contain at urntable nor a rotating shaft. It provides the independent control of injection unit and multi-material injection by the change of the core of the mold.

Rotating Shaft Solution

PRECISE ROTATING SHAFT CONTROLThe imported servo motor, synchronous belt and spline shaft provides precise and accurate position control for repeatable rotation control

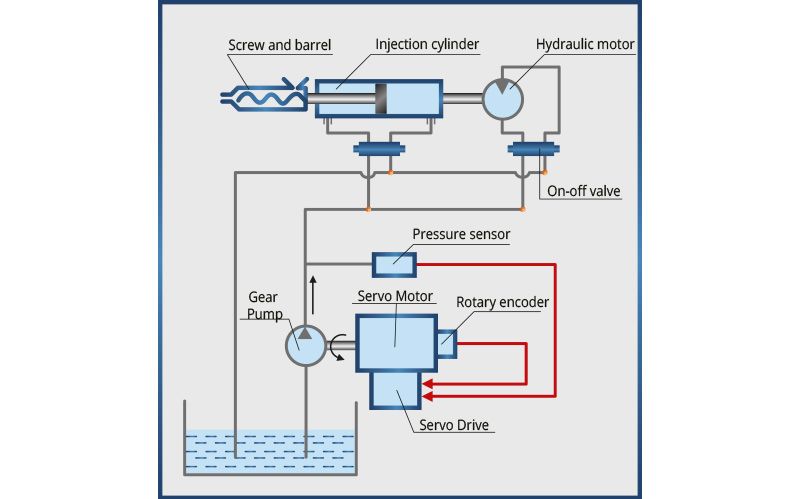

Energy Saving Drive System - Mars Technology

PATENTED SERVOMOTOR TO GEARPUMP DESIGNThe direct drive connection between the servo-motor and the gear pump provides excellent drive torque giving maximum acceleration and deceleration speeds for all machine functions. The Jupiter II Series is also equipped with the innovative “Mars Technology”.

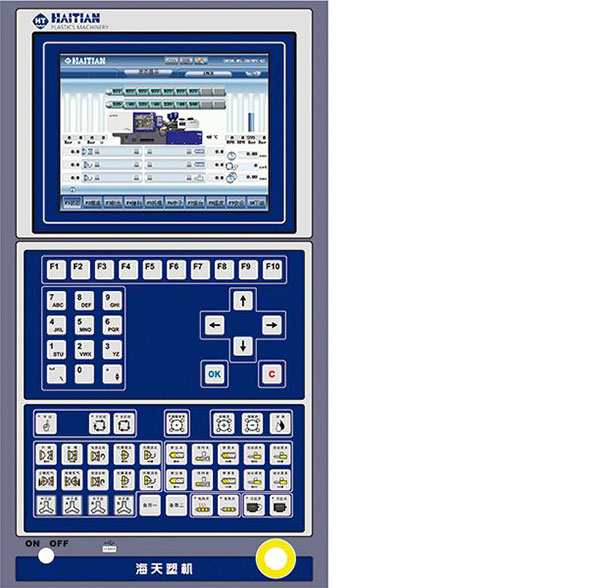

Control Technology

SOFTWARE & CONTROLThe control system for the multi component injection molding machines, with two CPU for the parallel data processing. The newest, easy to use computer control system, with a faster response cycle.